This article first appeared in the December 15, 1920 issue of Agrimotor magazine.

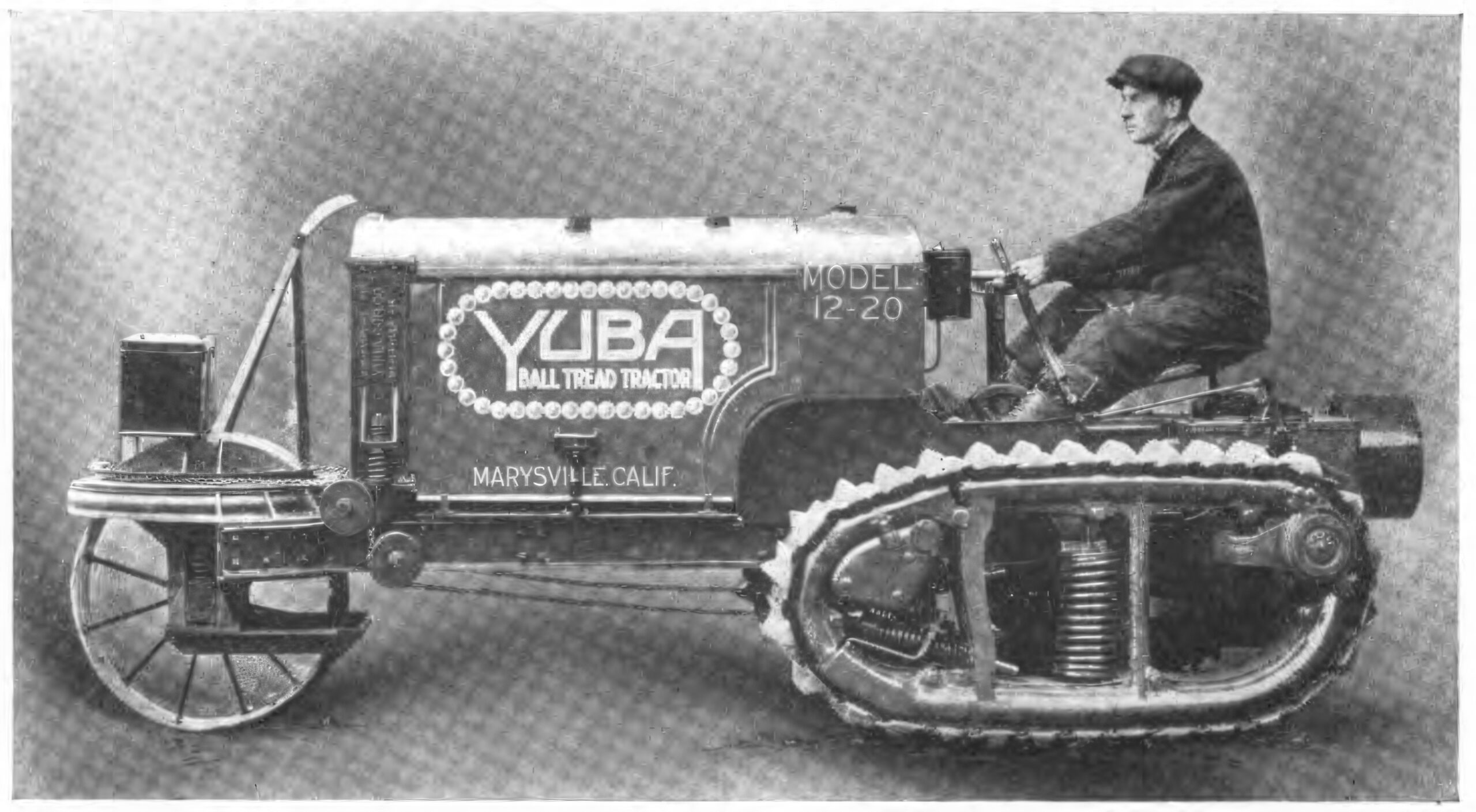

Pacific Coast Concern Builds a 20-35 hp. Model and a 12-20 hp. Model, Both Featuring a Crawler Tread Running on Balls.

YUBA TRACTORS are raised on the Pacific. Coast and being thoroughly acclimated to the conditions in that part of the country they are quite well known throughout that territory. There are two sizes built-the Yuba Oversize Model 20-35 horsepower and a 12-20 horsepower model.

As the two models are nearly identical in design and as the Oversize Model holds a priority claim in age, this article will be confined mainly to the details of that model.

The Yuba model is an endless track machine with a single wheel, known as

a “tiller” wheel, at the front. While properly grouped under the classification of “crawler type” it is rather a departure from common practice in crawler construction inasmuch as the tread is mounted on balls.

This is a distinctive feature patented and owned exclusively by the Yuba Manufacturing Co. For this reason the Yuba is sometimes referred to as the “Ball Tread Tractor.”

The frame is built up of heavy structural steel channels set on edge and heavily trussed and cross membered for stiffness. At the forward end is riveted a heavy cast member which carries the tiller wheel.

The rear end of the frame is braced securely by a heavy annealed steel cross member. To this member is attached the drawbar, the driver’s seat, the steering wheel and controls.

The engine used is the Wisconsin Model “M” of the heavy duty “T” head type. It has a bore of 534 inches and a stroke of 7 inches and delivers its rated power at 700 revolutions per minute. Cylinders are cast in pairs from close grained gray iron.

The engine is fastened to the frame by heavy cast I-section cross-members bolted by heavy through-bolts to each end of the upper half of the crankcase. The ends of these cross mem bers are bolted to cast brackets riveted to the frame. This type of construction effectually stiffens the frame, at the same time forming a good engine support.

Lubrication is by means of a combined splash and force feed system. A geared oil pump forces oil under pressure through a drilled crankshaft to all of the motor bearings and wrist pins. Cylinders are oiled by crank splash.

The oil system holds six quarts. A Bosch magneto furnishes the spark and a Stromberg carburetor equipped with a dry air type of cleaner is used.

Cooling water is circulated by means of a centrifugal pump. The radiator is of flat tube construction with a capacity of 15 gallons. It is protected by a cast-iron shell which is spring mounted to the tractor frame. The fan is mounted on ball bearings and driven at 1800 revolutions per minute by belt. The fan shaft is mounted in an eccentric which allows adjustment of the fan belt tension.

The starting crank is mounted on the right hand side of the tractor at the front of the engine. The power pulley is mounted on the left hand side at the front of the engine. Pulley sizes of 10, 12, 14 or 18 inches are optional.

The transmission gears, clutches and final drive shafts are all mounted in an oil and dust proof semi-steel cast case. The removable transmission cover is made of cast iron. All shafting is made from

chrome nickel steel forgings.

Power from the engine enters the transmission case through the medium of a flexible coupling and a short shaft mounting two sliding gears. On each side of this small shaft are mounted the two transmission shaft units-one for each crawler.

These transmission units are duplicates and are held in pillow block bearings formed by heavy webs cast in the bottom of the case.

The forward end of each transmission shaft carries two change speed gears meshing with the sliding gears mentioned previously. The rear end of the shaft connects with a Paragon marine type of clutch and reverse gear. The clutch is of the disk type and the reverse gear is of the planetary construction.

Thus the clutches are mounted between the transmission gears and the final drive. This style of construction gives two forward speeds and two reverse speeds.

The forward speeds are 2.06 and 3.28 miles per hour respectively. The reverse speeds are somewhat lower than these because of the additional gear reduction occasioned by the planetary gears in the reverse mechanism.

The clutch-shaft terminates in a bevel pinion meshing with a bevel gear on the inner end of the bull pinion shaft. All gears in the transmission are cut from nickel steel blanks, hardened and tempered. The final drive pinions are cut from nickel steel.

Hyatt roller bearings are used throughout the transmission. Oiling of the transmission gears, bearings and clutches is obtained by filling the case with transmission oil. However, grease cups are supplied on the outer ends of the bull pinion shafts where they pass through the case. Grease cups are also used to lubricate the front wheel bearings, fan-shaft, pump-shaft and power pulley shaft.

The ball tread unit is of unique construction. The spider, or main frame of this unit, which carries the drive sprocket, springs and ball race is made of annealed cast steel. To the rim of the spider are bolted high carbon steel ball raceways.

The front end of the raceway has a telescoping section which is held in position by a heavy coil vanad’um steel spring. The purpose of this construction is to provide an adjustment for maintaining a uniform track tension.

The track links are made of manganese steel and are held together by cold rolled case hardened steel pins. To each crawler link is bolted a pressed steel grouser and tread plate. These carry the sections of the tread-half of the ball race- way, and with them in place the link pins are effectively prevented from sliding out of place. The tread in operation rolls on 130 two and one-quarter inch specially hardened cold rolled chrome nickel steel balls.

The tread unit is mounted on a dead axle hung beneath the tractor frame. The drive sprocket and internal final drive gear are cast in one piece of manganese steel. The sprocket is mounted on Hyatt roller bearings on the dead axle.

The tread units are swung from the dead axles at a point one-fifth of the distance from the rear and oscillate on heavy coil vanadium steel springs. This construction helps to absorb shocks and vibrations from rough, uneven ground.

Lubrication of the treads is obtained from track oil pots which are hung in the forward part of the tread unit. These oil pots are filled with crude oil which is led by small pipes to various points in the ball race.

The tiller wheel is mounted in turntable fashion. It is controlled by means of cables from the steering wheel. Its axle is spring mounted. Nearly 1600 pounds of the tractor are carried on this wheel.

Mounted in front of the driver are the controls. They consist of the steering wheel, the clutch levers, gear shift lever and the spark and throttle controls. The steering wheel controls only the tiller wheel at the front while the clutch levers control each crawler tread individually.

Pushing both clutch levers forward starts the tractor forward, pulling them both back puts the machine in reverse; while pushing one lever forward and pulling one back will turn the machine in an eight foot circle. Directly in front of the operator’s seat is mounted the large cylindrical fuel tank which contains 38 gallons distillate and 7 gallons gasoline.

The 20-35 h.p. Yuba weighs 10,250 pounds and is 14 feet overall in length. The treads are 17½ inches wide and furnish a bearing area of 1680 square inches. This gives a ground pressure of 4.9 pounds per square inch.

The 12-20 h.p. model is equipped with a 4½ by 634 inch engine developing its rated horsepower at 700 revolutions per minute. The weight of this machine is 6750 pounds and it is 12 feet overall in length. The treads are 13 inches wide and furnish a bearing area of 1050 square inches. This gives a ground pressure of 5 pounds per square inch.

Both of these models may be equipped with special treads to meet particular conditions. They may also be furnished with half or full canopy tops or with complete lighting sets for night operation.

Reprinted from December 15, 1920 issue of Agrimotor magazine – In the Public Domain.

0