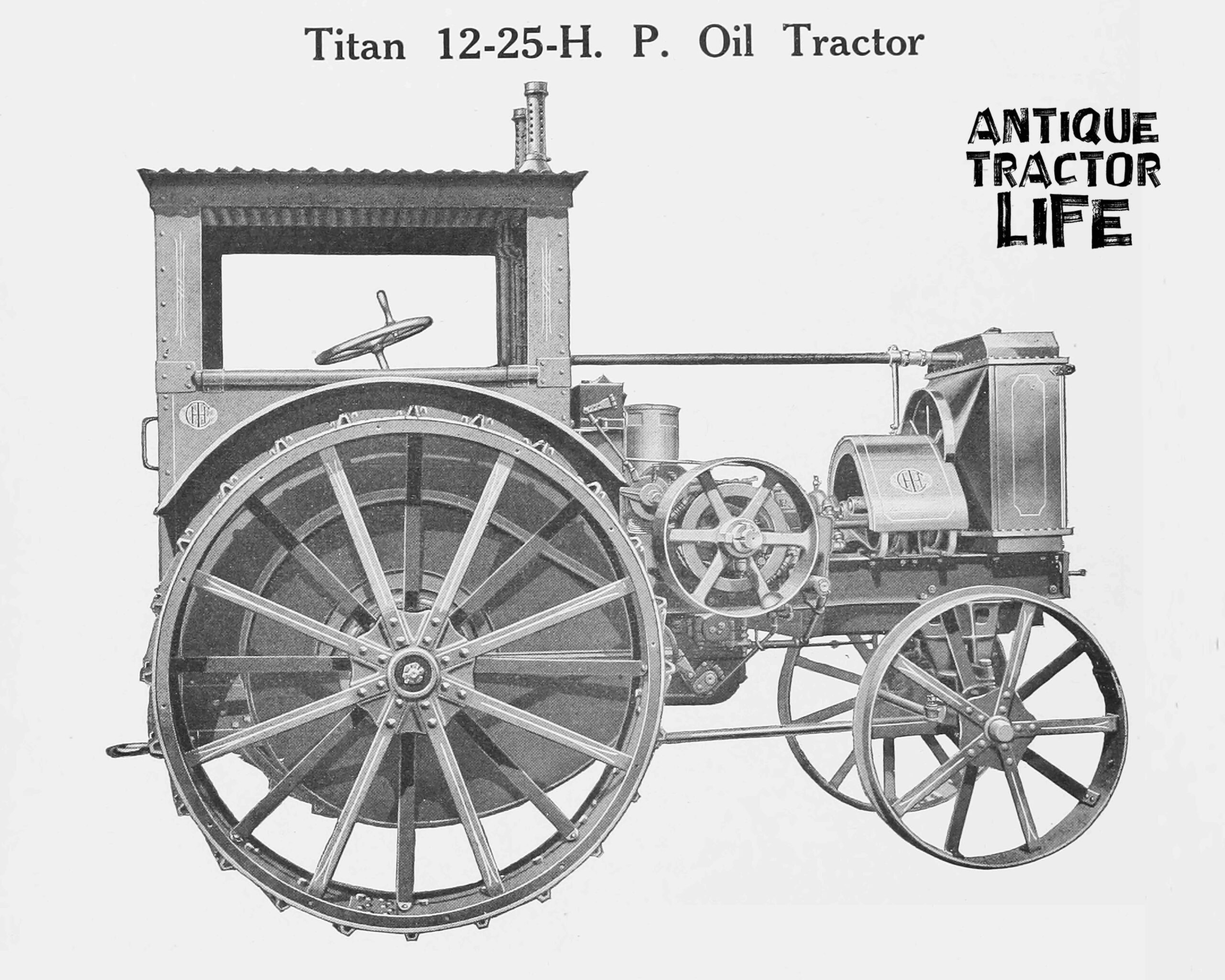

International Harvester built the Titan 12-25 Tractor (later re-rated as the Titan 15-30) at its Milwaukee, Wisconsin factory between 1914 and 1917. In total, only 818 units were produced, making it a rare and collectible machine today.

Engine

The Titan 12-25 was powered by a four-cylinder horizontal gasoline/kerosene engine, originally rated at:

- 12 horsepower on the drawbar

- 25 horsepower on the belt

- Operating at 575 RPM

The cylinders measured 4 ¼ inches in bore and 8 inches in stroke. Toward the end of production, the tractor was re-rated to 15-30 horsepower.

A unique feature of this tractor was its L-head (flathead) engine design, which placed both the intake and exhaust valves in the cylinder block rather than the head. While innovative, the design proved troublesome and was discontinued when International introduced the Titan 15-30.

Transmission & Performance

The transmission provided two forward speeds and one reverse.

- High gear: 2.4 mph top speed

- Low gear: 1.87 mph

Equipment & Accessories

The Titan 12-25 came fully equipped and ready to run, including:

- Built-in friction clutch pulley (22 inches in diameter, 8-inch face)

- Magneto

- Oil can and lubricating oil

- Necessary tools

Optional accessories included:

- Kerosene or acetylene headlights

- Special-sized pulleys

- 4-inch rear wheel extensions

- Cab curtains

- Stand lugs

Dimensions & Weight

- Front wheels: 40 inches diameter, 7-inch face

- Rear wheels: 66 inches diameter, 14-inch face

- Fuel tanks: 6 gallons gasoline, 30 gallons kerosene

- Length: 140 ½ inches

- Width: 85 ½ inches

- Height: 118 inches

- Shipping weight: approx. 9,580 lbs (4.8 tons)

About The L-Head or Flathead Engine Design

The design of an L-head or flathead engine is characterized by the placement of its valves and combustion chamber within the engine block, rather than in the cylinder head. Here are the key features of the L-head engine design:

- Valve Placement: In an L-head engine, both the intake and exhaust valves are positioned in the engine block beside the cylinders. This is in contrast to an overhead valve (OHV) engine, where the valves are located in the cylinder head above the combustion chamber.

- Combustion Chamber: The combustion chamber in an L-head engine is part of the engine block and is formed between the cylinder and the top surface of the engine block. The shape of the combustion chamber is often simple, and it resembles the letter “L” when viewed from the side, giving the engine its name.

- Simplicity: The L-head design is known for its simplicity. With fewer moving parts associated with valve mechanisms in the cylinder head, L-head engines are mechanically straightforward, making them easier to manufacture and maintain.

- Cooling: L-head engines typically have good cooling characteristics because the combustion chamber is in direct contact with the engine block, allowing efficient heat dissipation. However, this design may also lead to challenges in optimizing airflow and combustion efficiency.

- Historical Use: L-head engines were commonly used in early automotive applications, as well as in industrial and agricultural machinery. They were popular in the early to mid-20th century but have been largely superseded by more advanced engine designs, such as overhead valve (OHV) and overhead camshaft (OHC) configurations.

While the L-head design offered simplicity and ease of manufacturing, advancements in engine technology have led to the widespread adoption of overhead valve and other designs for improved efficiency, power, and emissions control in modern engines.

About International Harvester

International Harvester was a prominent American manufacturer of agricultural machinery, construction equipment, trucks, and household appliances. Founded in 1902 through the merger of several companies, including the McCormick Harvesting Machine Company and the Deering Harvester Company, International Harvester played a vital role in shaping the agricultural and industrial landscape of the United States.

The company became known for its innovative farm equipment, such as tractors, combines, and plows, contributing significantly to the mechanization of agriculture. International Harvester also ventured into the production of trucks and construction equipment, solidifying its presence in various sectors.

International Harvester went through significant changes over the years and ultimately evolved into a different entity. In 1985, International Harvester, facing financial difficulties and seeking to focus on its more profitable segments, sold the agricultural and construction equipment divisions to Tenneco Inc. In 1986, International Harvester rebranded the remaining portion of the company, primarily consisting of the truck and engine manufacturing divisions, as Navistar International Corporation.

Navistar continued to be a major player in the production of trucks, buses, and engines, while the agricultural and construction equipment divisions were no longer under the International Harvester umbrella. Over the subsequent years, Navistar faced various challenges, including financial struggles and legal issues related to engine technologies. In the early 2020s, Navistar agreed to be acquired by TRATON SE, a subsidiary of the Volkswagen Group, marking another chapter in the company’s history.

0